Talk to our lighting experts  +358 20 125 5800

+358 20 125 5800

![Industrial LED Lighting: Buyer’s Challenges [and how to overcome them]](https://greenled.com/wp-content/uploads/2018/12/industrial-led-lighting-buyers-challenges-1920x1080-1024x576.jpg)

December 13, 2018

Industrial LED Lighting: Buyer’s Challenges [and how to overcome them]

As a purchaser of industrial led lighting, you’re likely to have a lot on your mind.

Purchasing new lighting to industrial facilities isn’t something that happens frequently. Quite the opposite, lighting is rarely renewed and for many, it is the very first time dealing with lighting systems.

With demanding environments and business critical operations, concerns are bound to arise. How do I assure the lighting will last? Can we get it right for our facilities? Will it take massive changes to install? Can it be done?

In this article, we address the common challenges and concerns that arise in purchasing industrial led lighting. After reading this article, you will feel more informed and comfortable to move on with your purchasing process.

First and foremost: What are the main objectives of lighting?

In industrial facilities, the work tasks are typically detail-oriented, highly optimised, controlled or even risky. At the same time, minor mistakes, errors or lack of productivity can have business-critical consequences.

On that note, the significance of lighting in industrial settings is often underrated. More explicitly, facility managers and decision-makers are well aware of the energy savings aspect, but the effects of lighting on occupational safety and productivity are much less understood.

Apart from energy savings and environmental effects, the lighting conditions of an industrial facility greatly affect workplace safety and the productivity and alertness of employees. Productivity and flawlessness, on the other hand, quickly convert into cash.

Image: At Suosiola power plant, the quality of the lighting was recognized as one of the major factors affecting the safety and comfort of the employees. With the new LED lighting, the lighting quality reaches the EU standards and creates a workplace with improved safety and comfort. Read the full case study here.

So where should one start in creating safe and productive industrial lighting? Here are a few things to take into account:

High light levels improve the productivity and safety of industrial facilities. The EN-standards are a good starting point to decide on the lighting levels of spaces such as warehouses, production lines or assembly requiring precision works. While the standards set a minimum level, in industrial settings it’s wise to go above the standards in almost every occasion. As an example, raising light levels by 200 lux could increase task performance by as much as 6 %, reduce the number of rejects by 8 % and reduce accidents by 14 %.Source

Apart from light levels, the quality of the light makes a great difference. One of the things you want to pay attention to is glare control. The colour-rendering index (CRI) of the luminaires is also an important factor since a good CRI (RA≥ 80) helps in visual observing and makes the facility’s safety colours stand out both on-site as well as on the screens of the control room.

Suitability concerns – how to tell what’s right for us?

There are many kinds of industries with very different kinds of requirements, from dusty building materials to hygiene-requiring groceries. Moreover, some facilities have high ceilings and large areas to cover, some are shallow spaces with a lot of small rooms. The light output and durability of the lighting installation are concerns for anyone dealing with industrial led lighting, especially in harsh environments.

To ensure enough illuminance and endurance, the lighting needs to fit the environment it is installed to. While every industrial space needs its own kind of lighting, here are some common challenges to tackle:

Will there be enough light, even in high-BAYS?

In an industrial space, you need to have enough light regardless of the size or the height of the space. Therefore, make sure the light levels of the facilities are measured before and after the new installation. The higher the space, the more light output is needed to have the light reach all the way down to the floor.

But how do you know what the future lighting levels will be?

We recommend you ask the lighting supplier for a detailed lighting plan with real parameters in it. A lighting plan shows what the lighting levels will be in each area after the installation is completed. It’s also an important document to have in your pocket, should the end result not turn out as planned.

Apart from having a lighting plan, ask the lighting supplier about their experience and what kind of industrial spaces they have done. And remember, in an industrial setting you want to reach at least the minimum standard lighting levels, rather above.

Are there opportunities to CUSTOMISE the luminaires?

The customisation of LED luminaires can make a big difference in lighting performance. Apart from the light output, the right selection of optics can significantly improve the lighting of vertical surfaces, for example. This could be very important in logistic rooms, where the forklift drivers and collectors need to clearly see the signs and pallet markings.

Luminaires can also be customised by having different surface treatment options to suit the environmental effects of a particular setting.

How to ensure the endurance of the luminaires?

Depending on the environment, the lighting may need to tolerate moist, dust, heat, chemicals or impact. The cleaning methods differ, too – some luminaires may need to tolerate cleaning with alkaline detergents, some with a pressure washer.

Generally speaking, industrial settings require an IP class of ≥ 65, such as Greenled’s Sigma and Gamma luminaires. Also, the placement of the luminaires should fit the work tasks and eliminate the possibility of impact. Hanging light fixtures, for example, aren’t the best option in a facility operating with forklifts.

Apart from choosing a highly tolerant luminaire, discuss the specific conditions of your facilities with the lighting supplier. As an example, the operating temperatures of different luminaire variations differ from each other. As a purchaser, you want to understand what you are buying and the lighting manufacturer’s life claims should reflect your environment. This way, unpleasant surprises can be avoided.

Cost-efficiency – should we invest in lighting control?

Industrial facilities are often big in size and the utilisation rates of different spaces vary a lot. Some spaces inside the facility might have an ongoing production while some spaces have little or almost no traffic at all. In such a setting, lighting control plays a major role in energy-efficiency.

Lighting control ensures that the lighting is only on when needed, where needed. This will create significant energy savings and extend the lifespan of the luminaires. Moreover, automated lighting control saves resources and adds comfort since the employees don’t have to manually switch the lighting on and off.

Image: Along with Greenled luminaires, the logistics rooms at Huhtamäki Foodservice Nordic were equipped with motion detectors that automatically switch the lighting on and off to reduce energy use. At their best, presence control has brought added energy savings of 50 % in aisles with less traffic. Read the full case study here.

Practicality concerns – will it be burdensome?

As a manager of an industrial facility, you’re bound to worry about the practicality of installing a new lighting solution. The facilities are often retrofitted or the premises have been changed, renovated and altered many times over the years. Since lighting came first and the rest came later, the lighting points are randomly placed and rather difficult to reach.

Instead of worrying, think of the benefits. Investing in a new led lighting solution makes a big difference in maintenance needs. Maintaining an old lighting solution requires relatively many luminaire replacements that take a lot of man-hours to handle. Maintenance-free, on the other hand, means worry-free and significant savings in maintenance costs.

One of the common concerns in a lighting renewal is project management. Often, companies don’t have enough resources to dedicate someone in-house to manage the project. In such cases, it’s better to choose a supplier that can take full responsibility for the service, all the way from design to installation.

To the worry of practicality, there’s really only one thing you can do to make yourself at ease. Make sure the lighting supplier you decide to work with has experience in dealing with the lighting design and installation in demanding environments. With experience comes expertise.

Responsibility concerns – what if things don’t work out?

Traditionally, purchasing lighting solutions hasn’t been the simplest of all processes. Here’s why: there are many phases, many actors and a lot of effort involved.

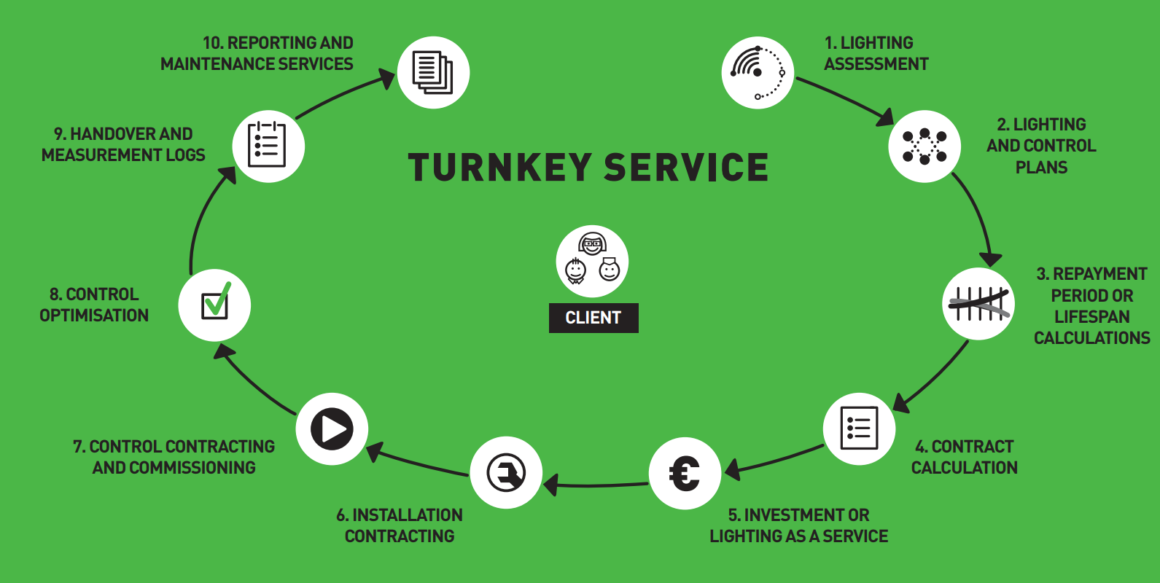

To justify the investment, at first, you need calculations to assure the upper management. After an initial decision, the process continues: the assessment of the spaces, the lighting design and planning, the mapping of potential suppliers, the installation contracting, the commissioning… and the list goes on.

What if instead, you would purchase the whole service from one single supplier, making it all easy and effortless to you? Working with a single supplier helps with responsibility concerns as well. With only one actor involved, you know who to contact in case you need help or if something isn’t quite as expected.

Image: The purchase process of a lighting solution might feel daunting. With all the different phases and actors, the whole process requires a lot of resources and responsibility concerns are bound to arise. The turnkey service concept with only one supplier makes the purchasing process easy and effortless for the client.

The financials – how to justify the investment?

As a rule, companies want to invest in their core business. In industrial settings, property management is rarely the number thing on the development list.

Moreover, justifying investments is a slow and rather laborious process. The payback period needs to be short and the strain on the balance sheet with any investment is carefully assessed by upper management.

Generally, LED lighting is easy to argue as the energy savings are usually immense compared to more traditional lighting technology. On top of that, led technology saves the environment and reduces the carbon footprint.

If that doesn’t help, think of the following: justifying a relatively large investment solely based on energy savings might feel like a difficult task. But what if you justify it based on improving workplace safety, flawlessness or productivity?

Instead of making an investment, many companies choose to purchase lighting as a service instead. Purchasing lighting as a service is a great option for any company wanting to save resources and avoid the strain on the balance sheet. Despite the monthly payment, the energy savings assure that savings start from day one, not to mention the other benefits.

Image: Traditionally, industrial lighting is considered an investment. Outotec Turula took a different approach and purchased led lighting as a service with a leasing agreement. The new lighting solution saves 70 % of energy and the leasing agreement releases capital for the core business. Read the full case study here.

Showcasing the results – how to prove it was all worth it?

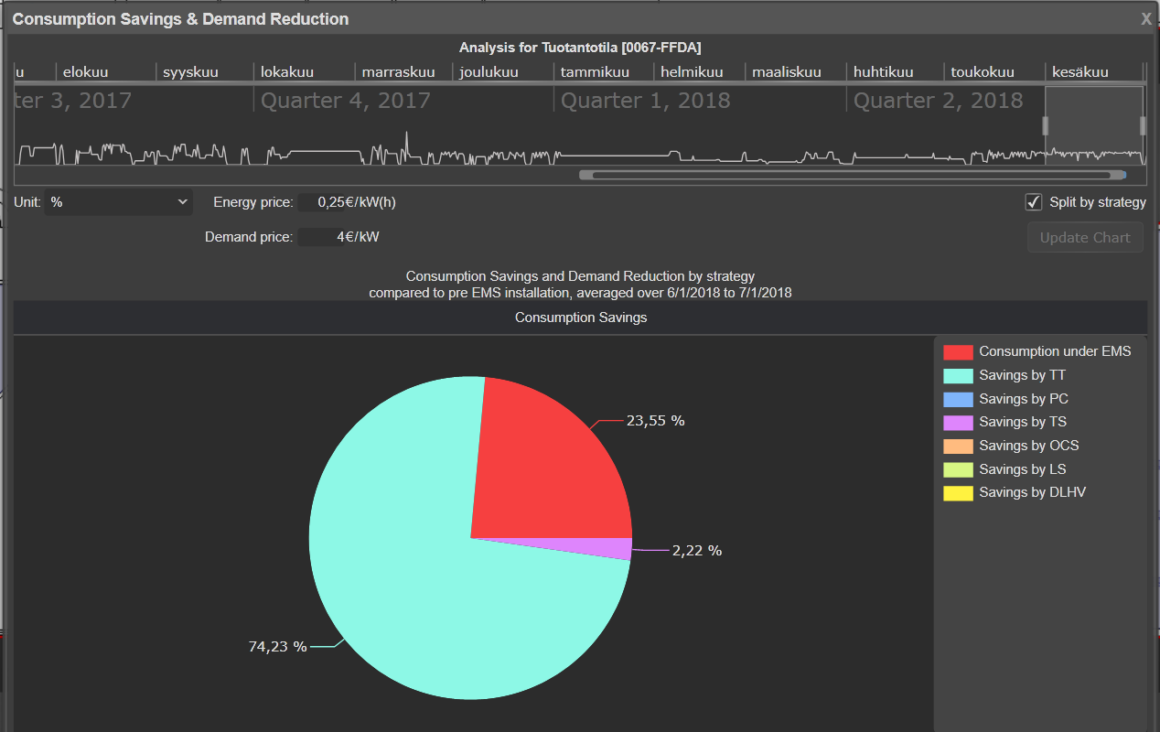

Anyone dealing with investments wants to prove the outcomes. Thanks to smart lighting systems, showcasing the results of an industrial LED lighting installation is convenient. A light management system produces detailed reports of the installation, including energy savings compared to the old lighting split between different strategies.

Image: At Greenled HQ, adjustable LED lighting with task tuning (TT) saves 75 % of energy compared to the previous fluorescent tubes that were constantly burning at full power. The energy saving reports can be accessed straight from the 3D Polaris software of ENCELIUM™ light management system. Read the full case study here.

Apart from detailed reports, a lighting management system has a bunch of other benefits. It helps you survey, track and verify the lighting of the building and adjust the lighting according to your needs. Moreover, a lighting management system opens up a view of the utilisation rates of a property and offers an integration interface to building management systems.

final words

After reading this article, we hope you have a good list of things to help you with the decision of purchasing industrial led lighting.

If you could take just one thing from this article, we hope it’s the following: discuss with the people working under the luminaires. Including different stakeholders in the conversation will help you understand the requirements of the lighting and the effects of industrial lighting that reach beyond simply saving energy or cutting costs. We guarantee this little bit of extra thought will pay itself back in ways that matter most: productivity, workplace safety and comfort.